electrical discharge machining working principle

It works on the thermo-electrical phenomenon. Ad Makino EDMs are designed for supreme reliability and industry leading precision.

Electro Discharge Machining Edm Steemit

Low Prices on Millions of Books.

. The workpiece is connected to the ve terminal it. Some of them include. January 6 2021 WMTMETAL 0 Comments Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process.

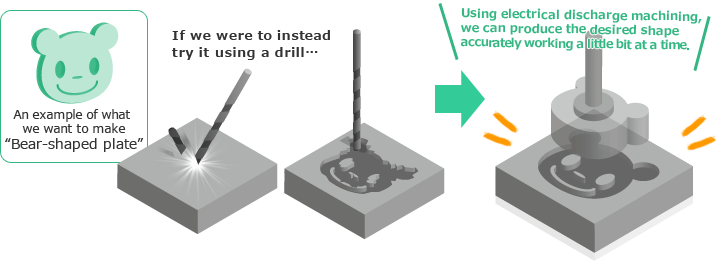

Work on Any Type of Electrically. Explanation of EDMAudio. Electric discharge machining also known as spark erosion electro-erosion or spark machining is a metal removal process that uses an interrupted electric spark discharge between the.

GoldenSources meta data and data lineage capabilities are ideal to create a shared architecture for compliance with the BCBS 239 principles for risk data aggregation and risk. The workpiece and the tool are electrically connected to dc electric power. Ad Free 2-Day Shipping with Amazon Prime.

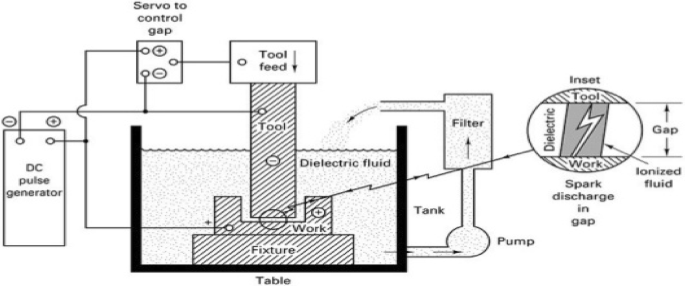

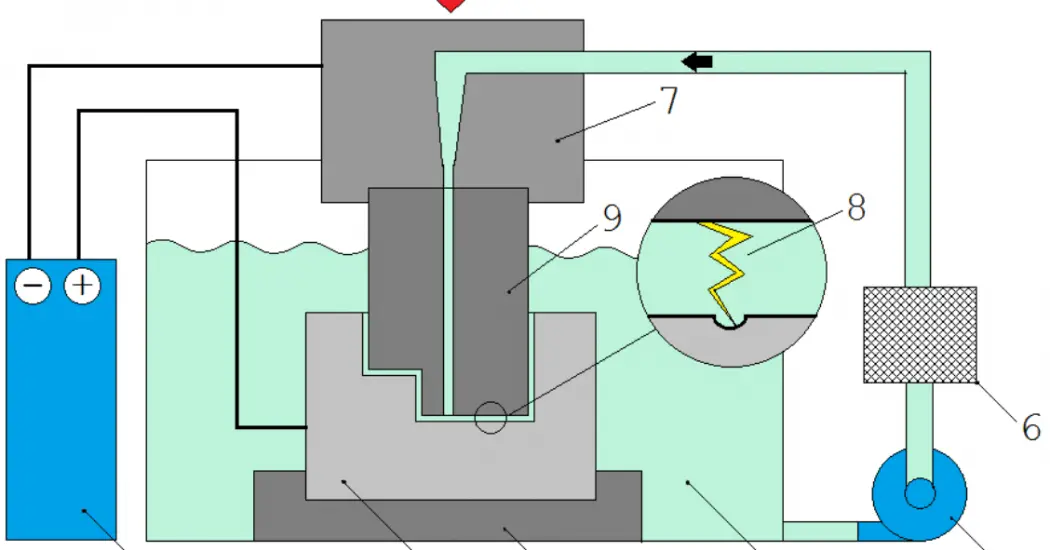

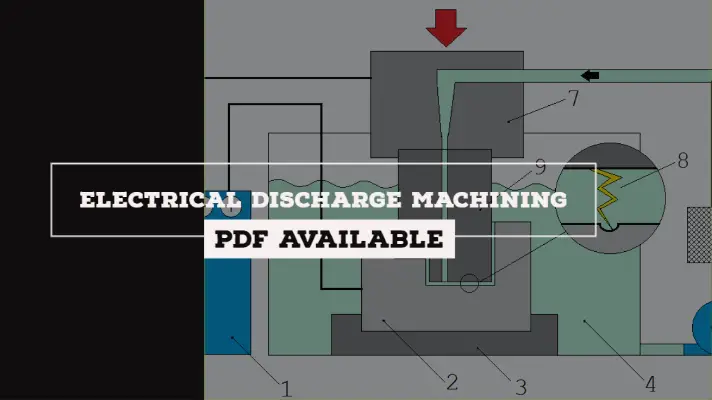

Electrical discharge machining EDM is a process of removing material by exposing it to reoccurring controlled electric discharge. Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin. Introduction to Electric Discharge Machining EDM 2.

Electrical discharge Machining Working Principle. It is suitable for thermoelectric phenomena. Advantages of Electrical Discharge Machining.

Mechanics of EDM 3. In this article we will discuss about the electric discharge machining EDM- 1. There are several unique advantages associated with EDM manufacturing.

Ad Full suite of CNC machining services including the latest in wire EDM machining. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. For quality parts delivered on time choose Xometry cnc machining services.

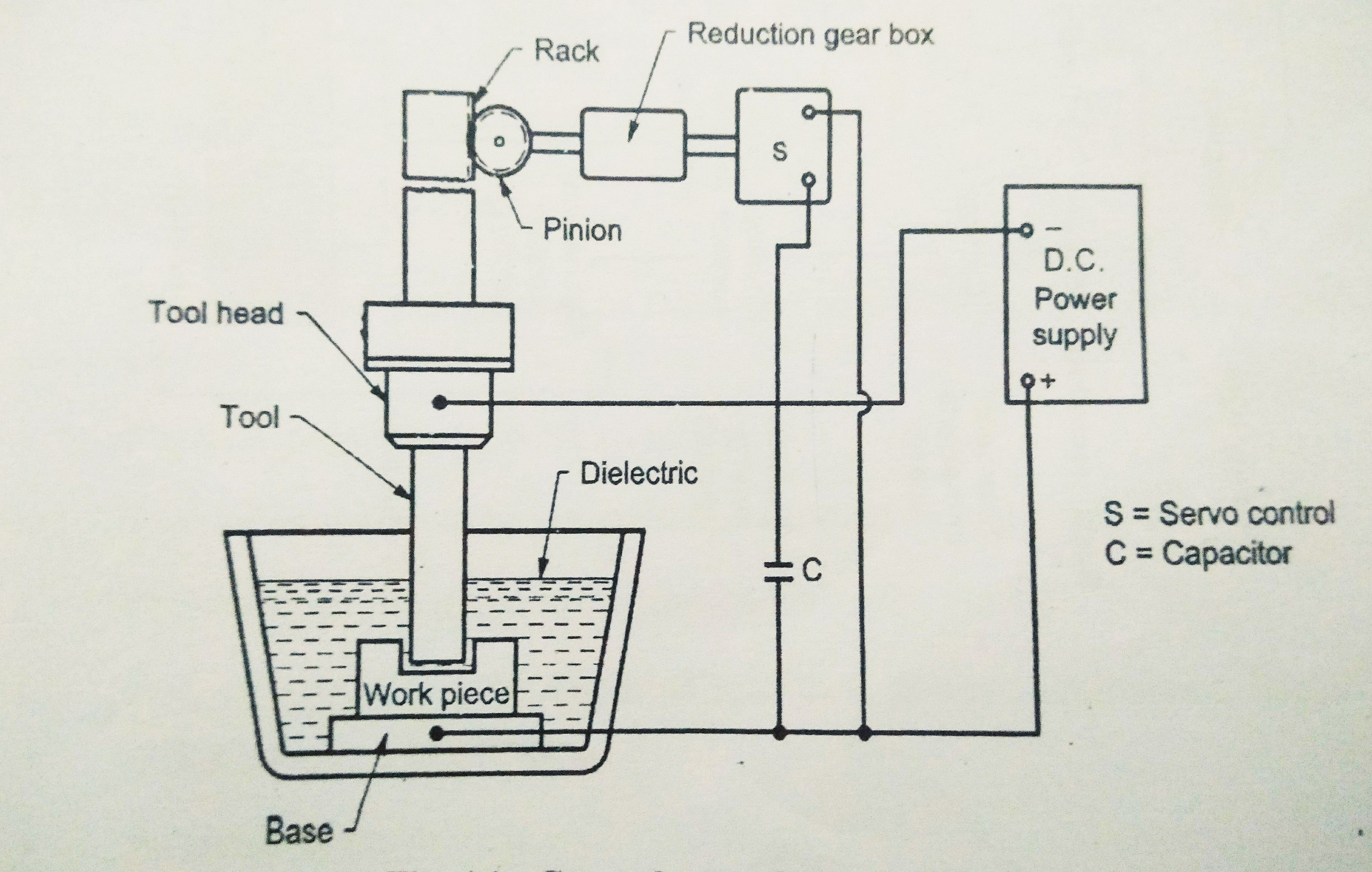

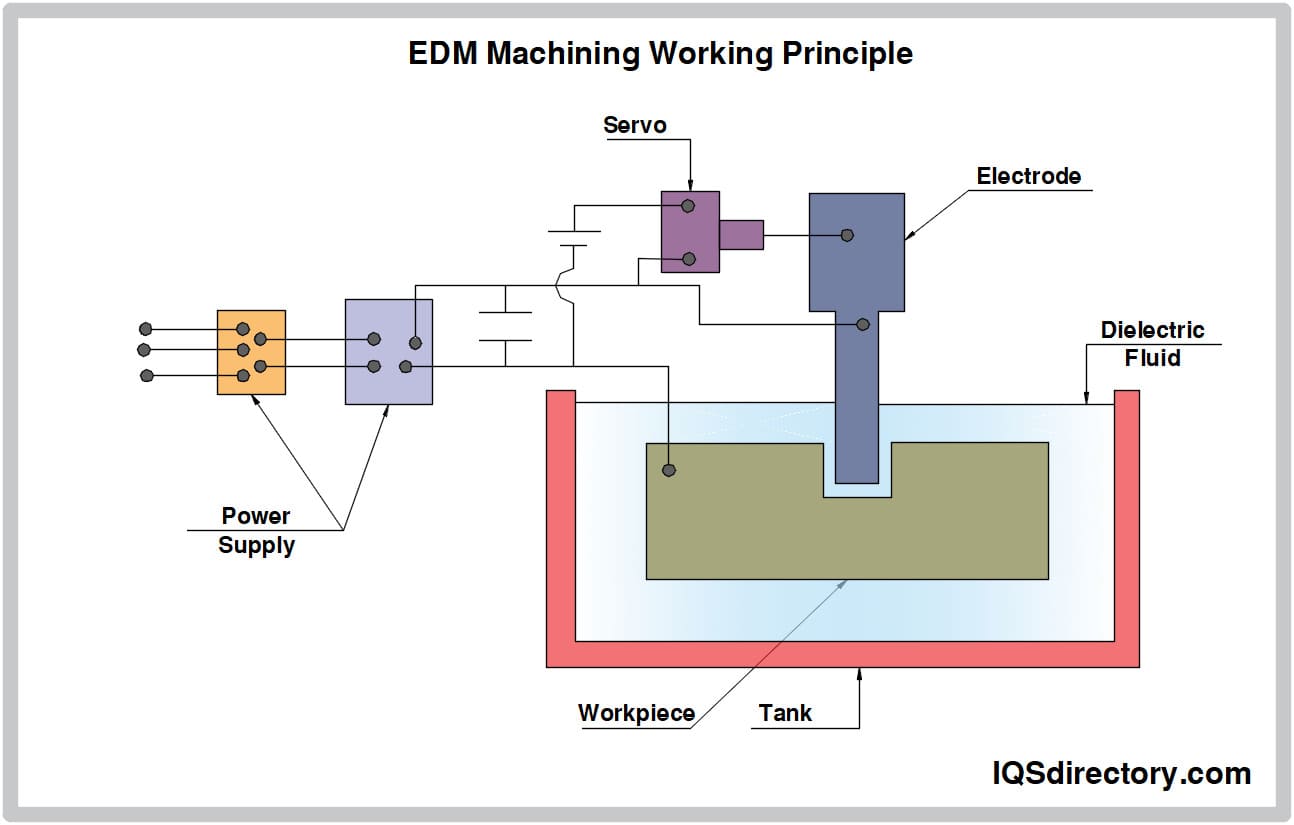

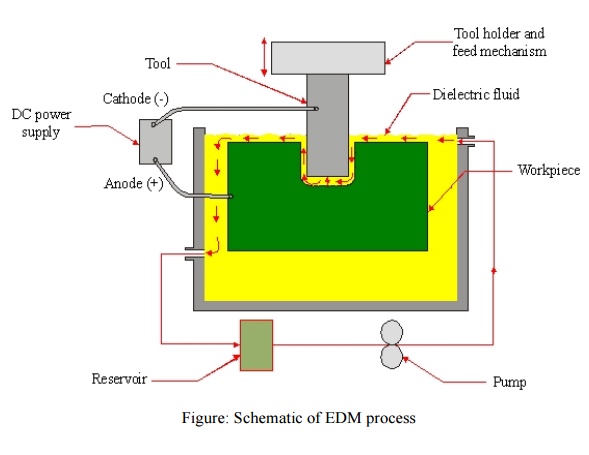

Electric discharge machining EDM is the removal of materials conducting electricity by an electrical discharge between two electrodes Workpiece and tool a dielectric. Electrical Discharge machining is the process of metal removal from the work surface due to an erosion of metal caused by electric spark discharge between the two electrodes tool cathode. Electrical discharge machining EDM is a subtractive manufacturing process converting electrical discharge into thermal energy.

Working Principle of Electric Discharge Machining. Our machines are designed for the highest level of accuracy reliability and productivity. The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion.

Edm Machining Components Types Applications And Advantages

Principles Of Electrical Discharge Machining And Non Consumable Electrode Circuits The Art Of Monodzukuri Techniques For Creating Things Sodick Magazine Sodick

Electrical Discharge Machining Edm

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Working Principles Of Electrical Discharge Machining

Working Principle Of Wedm Download High Resolution Scientific Diagram

Fig Working Principle Of Edm Process Download Scientific Diagram

Recently Evaluated Electrical Discharge Machining Edm Process Performances A Research Perspective Sciencedirect

What Is Wire Edm Electrical Discharge Machining Xact

Influence On Machinability And Form Tolerance Of Inconel 718 In Edm Using Different Diameter Multi Hole Cu Electrodes Springerlink

Electrical Discharge Machining Edm Parts Working Principle Advantages Disadvantages Applications Pdf

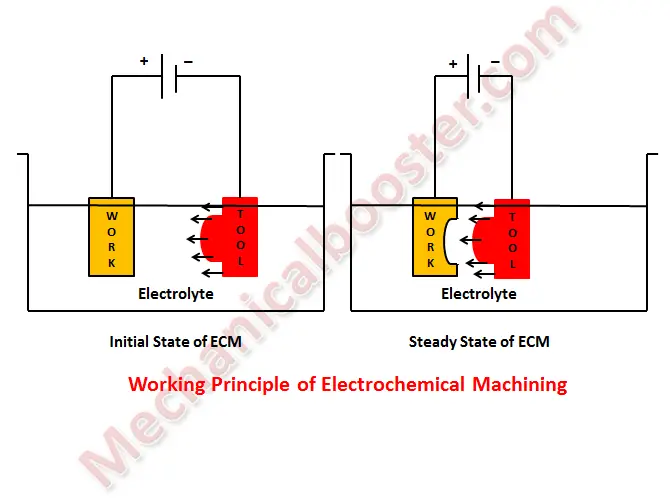

Electrochemical Machining Ecm Working Principle Equipment Advantages And Disadvantages With Application Mechanical Booster

Electrical Discharge Machining Wikipedia

Solved Non Traditional Machining Processes Review Questions Chegg Com

Electrical Discharge Machining Edm Parts Working Principle Advantages Disadvantages Applications Pdf

Edm Machining Construction And Working Principle Discussed

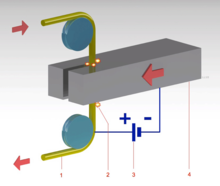

Wire Edm Wire Electro Discharge Machining Engineeringclicks